Calibration Equipment

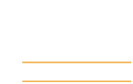

CTAS-BTMT Series Mechanical Wrench Calibration System

About the CTAS-BTMT Series Mechanical Wrench Calibration System

CTAS-BTMT Series have a system accuracy of 0.5% indicated reading for top 90% of tester range. This torque tester is designed to provide multiple torque ranges with one display. It is well suited for hand or power tool validation/certification. These instruments are available with 2, 3 or 4 internal transducers, to a maximum of 750 Lbf/ft (imperial) or 1016Nm (metric) and also include a transducer port for connecting an external transducer for ranges over 750 Lbf/ft (imperial) or 1016Nm (metric) capacity. This system is available in various configurations and can be custom built to meet your requirements. Multiple torque ranges, 2, 3, 4, 5 or more transducers with one display. This unit can provide all the torque transducers required in one tool room or calibration lab. Low cost, high quality, ease of use and with the ability to add data management features with the addition of software makes the CTAS-BTMT testers indispensable.

Rundown Fixtures

1/4” and 3/8” rundown fixtures (up to 1000 Lbf/in, 112Nm) are included, 1/2”, 3/4” and larger rundown kits are available but they are optional and priced separately.

Tool, Data Management Software, and Templates

CanTorque offers several PC software applications for facilitating tools test management and data archiving or printing. Please contact CanTorque for aid in selecting appropriate software for your application.

CTAS BTMT Series Desktop Torque Testers (with Display)

CTAS BTMT Series Desktop Torque Testers with display can be built with the transducers listed below. The external transducer port can support any size/capacity transducer that we manufacture – from 10 Ozf/in to 50,000 Lbf/ft (imperial) 0Nm to 67,790Nm (metric). External transducers include the cable.

Transducers

The CTAS-BTMTE transducers are mounted in a housing that is designed with through holes for mounting to a bench or a mounting plate. There are two standard sizes; one small housing for all transducers up to 250 Lbf/ft (imperial) or 338Nm (metric) and the large housing for transducers up to 2000 Lbf/ft (imperial) or 2711Nm (metric).

Our stationary transducers are supplied with internal square drives; 1/4”, 3/8”, 1/2”, 3/4” and 1” depending on capacity. Various rundown fixtures are available that are designed to fit in the internal square drive providing a means of testing power tools. Our transducers are manufactured from stainless steel, precision machined, strain gaged and thoroughly.

Transducers

The CTAS-BTMTE transducers are mounted in a housing that is designed with through holes for mounting to a bench or a mounting plate. There are two standard sizes; one small housing for all transducers up to 250 Lbf/ft (imperial) or 338Nm (metric) and the large housing for transducers up to 2000 Lbf/ft (imperial) or 2711Nm (metric).

Our stationary transducers are supplied with internal square drives; 1/4”, 3/8”, 1/2”, 3/4” and 1” depending on capacity. Various rundown fixtures are available that are designed to fit in the internal square drive providing a means of testing power tools. Our transducers are manufactured from stainless steel, precision machined, strain gaged and thoroughly.

Product Features

System accuracy of ±0.5% of indicated reading, top 90% of range.

- Welded steel housing

- Designed to facilitate hand or power tool testing

- Intuitive User interface.

- Feature sets include Peak, First Peak and Track modes, upper and lower limits, memory and serial data output

Specifications

Accuracy: +/-.5% bidirectional

Engineering Units: Ozf/in, Lbf/in, Lbf/ft, Nm, cNm, KgfCm, gfCm, Kgfm

Modes: Track, Peak, or First Peak

Housing: Heavy Duty Aluminum

Batteries: Rechargeable NiMH (10-12 hrs continuous use)

Weight: 3.5lbs (imperial), 1.5kg (metric)

Display: Segmented, Four Active Digits with menus

Dimensions: 3″x4.5″x8.5″ (imperial), 76x114x215 (metric)

Internal Transducers

| MODEL | CAPACITY REQUIRED (imperial) | CAPACITY REQUIRED (metric) | DRIVE SIZE |

|---|---|---|---|

| CTAS-BTMT-100-O | 10-100 Ozf/in | 7.06t70.61 cNm | 1/4″ |

| CTAS-BTMT-10-I | 1-10 Lbf/in | 11.29-112.95 cNm | 1/4″ |

| CTAS-BTMT-25-I | 2.5-25 Lbf/in | 28.24-282.46 cNm | 1/4″ |

| CTAS-BTMT-50-I | 5-50 Lbf/in | 56.49-564-92 cNm | 1/4″ |

| CTAS-BTMT-100-I | 10-100 Lbf/in | 1-11 | 1/4″ |

| CTAS-BTMT-250-I | 25-250 Lbf/in | 2-28 | 1/4″ |

| CTAS-BTMT-500-I | 50-500 Lbf/in | 5-56 | 3.8″ |

| CTAS-BTMT-100-F | 10-100 Lbf/in | 33-338 | 1/2″ |

| CTAS-BTMT-150-F | 15-150 Lbf/in | 81-813 | 1/2″ |

| CTAS-BTMT-250-F | 25-250 Lbf/in | 101-1016 | 1/2″ |

| CTAS-BTMT-600-F | 60-600 Lbf/in | 135-1355 | 3/4″ |

| CTAS-BTMT-750-F | 75-750 Lbf/in | 101-1016 | 3/4″ |

External Transducers

| MODEL | CAPACITY REQUIRED (imperial) | CAPACITY REQUIRED (metric) | DRIVE SIZE |

|---|---|---|---|

| CTAS-BTMTE-10-O | 10-100 Ozf/in | 7.06t70.61 cNm | 1/4″ |

| CTAS-BTMTE-50-O | 10-100 Ozf/in | 3.53-35.30 cNm | 1/4″ |

| CTAS-BTMTE-100-O | 10-100 Ozf/in | 7.06t70.61 cNm | 1/4″ |

| CTAS-BTMTE-10-I | 1-10 Lbf/in | 11.29-112.95 cNm | 1/4″ |

| CTAS-BTMTE-25-I | 2.5-25 Lbf/in | 28.24-282.46 cNm | 1/4″ |

| CTAS-BTMTE-50-I | 5-50 Lbf/in | 56.49-564-92 cNm | 1/4″ |

| CTAS-BTMTE-100-I | 10-100 Lbf/in | 1-11 | 1/4″ |

| CTAS-BTMTE-250-I | 25-250 Lbf/in | 2-28 | 1/4″ |

| CTAS-BTMTE-500-I | 50-500 Lbf/in | 5-56 | 3.8″ |

| CTAS-BTMTE-100-F | 10-100 Lbf/in | 13-135 | 1/2″ |

| CTAS-BTMTE-150-F | 15-150 Lbf/in | 20-203 | 1/2″ |

| CTAS-BTMTE-250-F | 25-250 Lbf/in | 33-338 | 1/2″ |

| CTAS-BTMTE-600-F | 60-600 Lbf/in | 81-813 | 3/4″ |

| CTAS-BTMTE-750-F | 75-750 Lbf/in | 101-1016 | 3/4″ |

| CTAS-BTMTE-1000-F | 100-1000 Lbf/in | 135-1355 | 1″ |

| CTAS-BTMTE-2000-F | 200-2000 Lbf/in | 271-2711 | 1″ |

Accessories

| MODEL | DESCRIPTION | DRIVE SIZE | HEX TEST BOLT (imperial) | HEX TEST BOLT (metric) | HEX (inch) | Hex (mm) |

|---|---|---|---|---|---|---|

| CTAS-RD-200-O | 200 Ozf/in or 114cNm rundown fixture | 1/4″ | 1/4 x 20 | 6.25 x 508 | 3/16 | 4.76 |

| CTAS-RD-150-I | 150 Ozf/in or 16cNm rundown fixture | 1/4″ | 1/4 x 20 | 6.25 x 508 | 3/16 | 4.76 |

| CTAS-RD-500-I | 500 Ozf/in or 56Nm rundown fixture | 3/8″ | 3/8 x 16 | 9.52 x 406 | 5/16 | 7.94 |

| CTAS-RD-250-F | 250 Ozf/in or 338Nm rundown fixture | 1/2″ | 5/8 x 18 | 10.87 x 457 | 1/2 | 12.7 |

| CTAS-1050-I | Insert Adapter (1″M x 1/2″F) | |||||

| CTAS-1075-I | Insert Adapter (1″M x 3/4″F) | |||||

| CTAS-7550-I | Insert Adapter (3/4″M x 1/2″F) |